Achieving MDR Compliance for Single-Use Non-woven Medical Consumables: Key Requirements for Obtaining the CE Certificate

Introduction:

Introduction:

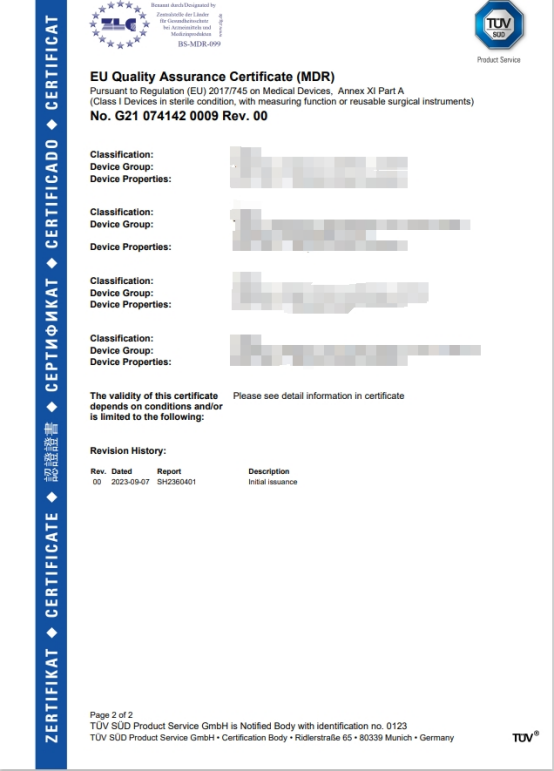

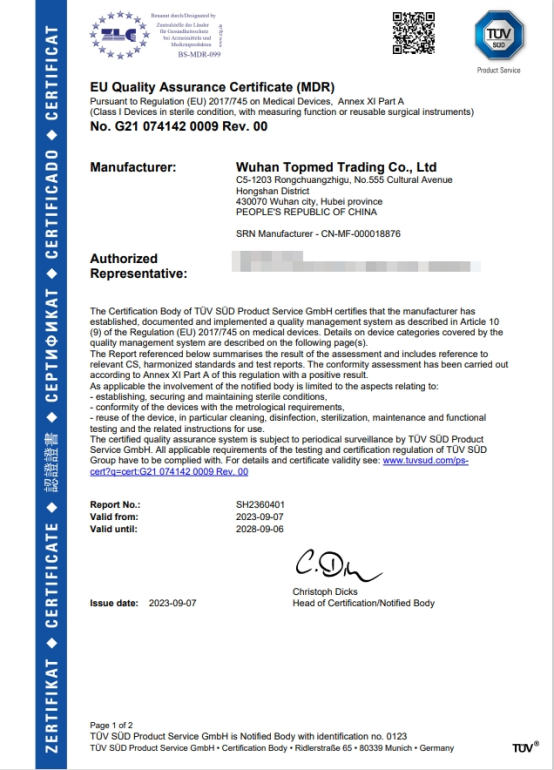

The Medical Device Regulation (MDR) in the European Union (EU) has set forth stringent requirements to ensure the safety and efficacy of medical devices, including single-use non-woven medical consumables. Manufacturers seeking to obtain the CE certificate for these products must navigate a complex regulatory landscape and adhere to specific criteria outlined by the MDR. This comprehensive analysis delves into the essential conditions that must be met to achieve MDR compliance and secure the CE certificate for single-use non-woven medical consumables.

1. **Classification and Conformity Assessment:**

a. **Risk Classification:**

The first step in the MDR compliance process involves accurately classifying the single-use non-woven medical consumable based on its intended use, potential risks, and duration of contact with the patient. The classification determines the conformity assessment route that manufacturers must follow.

b. **Conformity Assessment Procedures:**

Manufacturers must select the appropriate conformity assessment procedure based on the device's classification. This may involve self-certification, involvement of a Notified Body, or a combination of both. Notified Bodies play a crucial role in assessing the conformity of higher-risk devices.

2. **Clinical Data and Performance Evaluation:**

a. **Clinical Evidence:**

Manufacturers must compile comprehensive clinical data to support the safety and performance claims of the single-use non-woven medical consumable. This involves conducting clinical studies or, in some cases, leveraging existing data for similar products. The clinical evidence must align with the General Safety and Performance Requirements (GSPR) outlined in Annex I of the MDR.

b. **Performance Evaluation:**

A thorough performance evaluation is essential, assessing aspects such as biocompatibility, sterility, and mechanical properties. This evaluation is critical in demonstrating that the single-use non-woven medical consumable meets the essential requirements for safety and performance.

3. **Quality Management System (QMS):**

a. **ISO 13485 Compliance:**

MDR requires manufacturers to establish and maintain a Quality Management System (QMS) in compliance with ISO 13485. This standard outlines the necessary processes and controls to ensure the consistent quality of medical devices throughout their lifecycle.

b. **Post-Market Surveillance (PMS) and Vigilance:**

Manufacturers must implement robust post-market surveillance systems to monitor the performance of the single-use non-woven medical consumable once it reaches the market. Additionally, a vigilant approach to reporting and investigating adverse events is crucial for ongoing compliance.

4. **Unique Device Identification (UDI):**

a. **UDI System Implementation:**

MDR mandates the implementation of a Unique Device Identification (UDI) system for traceability purposes. Manufacturers must assign a unique identifier to each unit of the single-use non-woven medical consumable, facilitating accurate identification and tracking throughout the supply chain.

b. **EUDAMED Registration:**

Manufacturers are required to register relevant data, including UDI information, in the European Database on Medical Devices (EUDAMED). This centralized database enhances transparency and facilitates effective post-market surveillance.

5. **Labeling and Instructions for Use:**

a. **Labeling Requirements:**

The labeling of single-use non-woven medical consumables must comply with MDR specifications, providing clear and accurate information on the device's intended purpose, instructions for use, and any necessary warnings or precautions.

b. **Instructions for Use:**

Manufacturers must provide comprehensive instructions for use to ensure that healthcare professionals and end-users can safely and effectively use the medical consumable. This includes information on proper storage, handling, and disposal.

6. **Cooperation with Notified Bodies:**

a. **Notified Body Involvement:**

Depending on the risk classification, manufacturers may need to engage a Notified Body for the conformity assessment. Close collaboration with the Notified Body is essential throughout the assessment process to address any queries and ensure a smooth certification process.

7. **Transition Period and Deadline:**

a. **Transition Period:**

Manufacturers should be aware of the transition period provided by MDR for the compliance of existing products. Understanding the timeline for transitioning from the Medical Device Directive (MDD) to MDR is crucial to avoid disruptions in the market.

b. **Deadline Awareness:**

Manufacturers must be mindful of the MDR deadlines and work proactively to ensure that their single-use non-woven medical consumables meet the new regulatory requirements within the specified timeframes.

Conclusion:

Achieving MDR compliance and obtaining the CE certificate for single-use non-woven medical consumables involves a multifaceted process that demands meticulous attention to detail and a commitment to patient safety. By navigating the classification, conformity assessment, clinical evaluation, and quality management requirements, manufacturers can position themselves to meet the rigorous standards set by the MDR. Proactive engagement with Notified Bodies, implementation of robust post-market surveillance, and adherence to labeling and UDI requirements are essential elements in securing and maintaining MDR compliance. As the healthcare landscape continues to evolve, manufacturers must stay vigilant to regulatory updates and collaborate with stakeholders to ensure the ongoing safety and efficacy of their medical consumables in the European market.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

LA

LA